“Lost-wax” and

“water-glass” casting

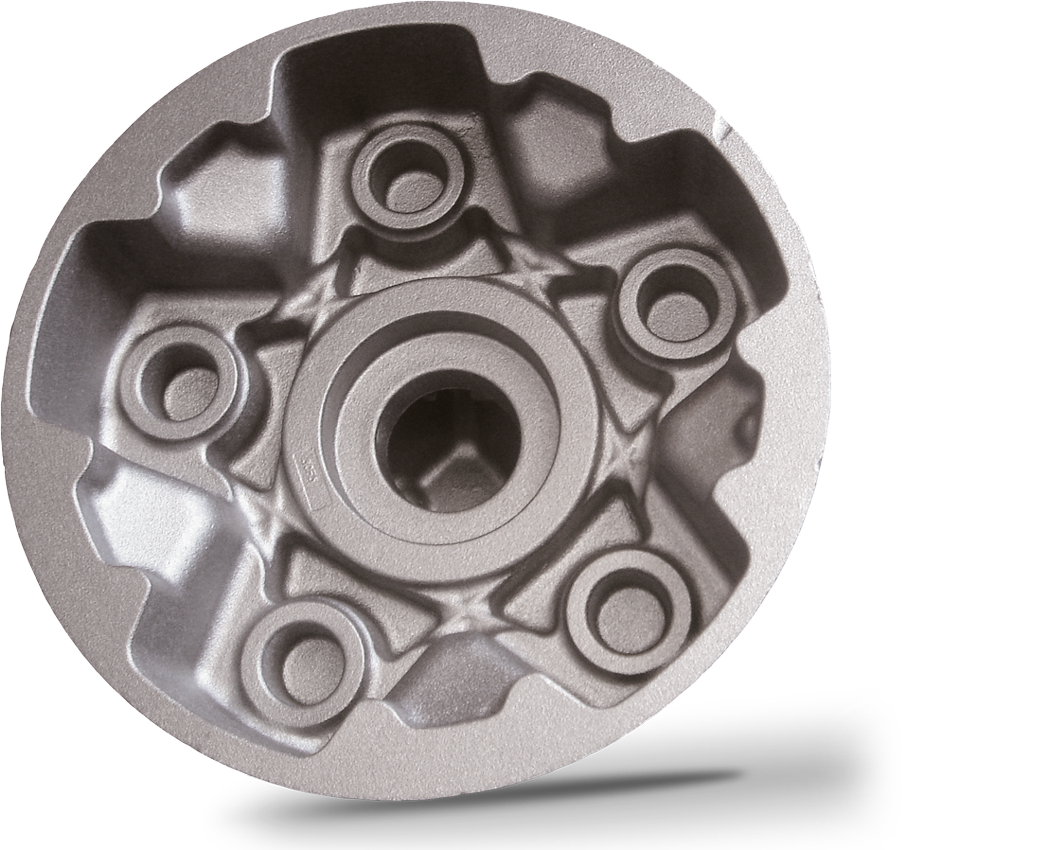

Lost-wax and water-glass casting are advanced processes used in the production of investment casting, which allow for high precision and quality components to be obtained. Lost-wax investment casting is a technique that dates back thousands of years, permitting complex pieces to be made with fine details and a smooth surface.

Water-glass technology, rather, can only be used for carbon steel and offers the dual advantage of a surface quality comparable to lost-wax investment casting and a lower cost similar to the more well-known but coarse sand casting. Both processes are widely used in the production of mechanical, plant engineering and shipbuilding components, offering solutions tailored to the needs of our customers.

Our foundry specialises in the production of investment casting in stainless steel and carbon steel, made to the specific designs of our customers.

Our versatility does not stop there – we are able to perform castings with non-ferrous metals (some aluminium and copper alloys) using lost-wax casting processes (investment casting), offering a wide range of additional services that also include mechanical processing of semi-finished products, surface finishes (mirror polishing, galvanising, anodising, burnishing, etc.), rapid prototyping (even in small series with silicone moulds), die casting and MIM (Metal Injection Moulding), to fully meet the most specific needs of the industrial sector.

For steel investment casting, in addition to the established lost-wax technique for lost-wax investment casting, we offer an advanced technological solution known as water-glass.

This method presents significant advantages, including a surface quality similar to traditional investment casting, a reduced cost similar to sand casting and a significantly higher quality of raw material thanks to the absence of sand inclusions or blowing, guaranteeing excellent results at every stage of production.

Our range of materials is extremely varied and includes stainless steel in all its grades, Duplex, Superduplex, Hastelloy, copper alloys (bronze, brass, etc.) and aluminium alloys.

the art of shaping material

In addition to mechanical processing, we offer a series of additional targeted services. These include: heat treatments to improve the mechanical properties of the components, surface finishes such as satin and mirror polishing that are particularly appreciated in the shipbuilding and food sectors, electropolishing on stainless steel and galvanising/burnishing on carbon steel, for an impeccable and long-lasting final result.

Lario Industry uses the highest quality materials and provides a complete range of services to meet every production need.

from casting to forming