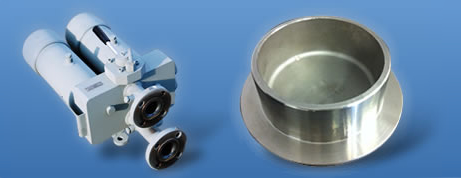

PRECISION INVESTMENT CASTING BY “LOST WAX” AND “WATER GLASS” PROCESS

Our core business: production of steel and non-ferrous castings through “lost wax” process; machining (even starting from solids and bars) according to customer’s drawing; fast prototyping and die-casting.We complete the range of our services with the mere machining of semi-finished items, even the most demanding ones such as the plastic injection moulds meant for production of thermo-plastic items.

Learn more about the precision investment casting by lost wax

As to steel castings, besides the common “Lost Wax” casting method, we offer also the so called “Water Glass” advanced technology, granting three main advantages:

The range of materials we deal in goes from stainless steel (in all its grades) to copper alloys (bronze, brass etc) and aluminium alloys.

- a good surface quality, similar to the one obtained by lost wax

- a low cost, similar to sand casting prices

- a high quality of the raw casting, markedly better in respect to sand casting due to the total absence of sands inclusions and blowholes.

The range of materials we deal in goes from stainless steel (in all its grades) to copper alloys (bronze, brass etc) and aluminium alloys.